EMERGING TECHNOLOGIES

PARIS AIR SHOW NEWS: Tech Partnership Accelerating Digital Engineering with Simulation Tools

By Laura Heckmann

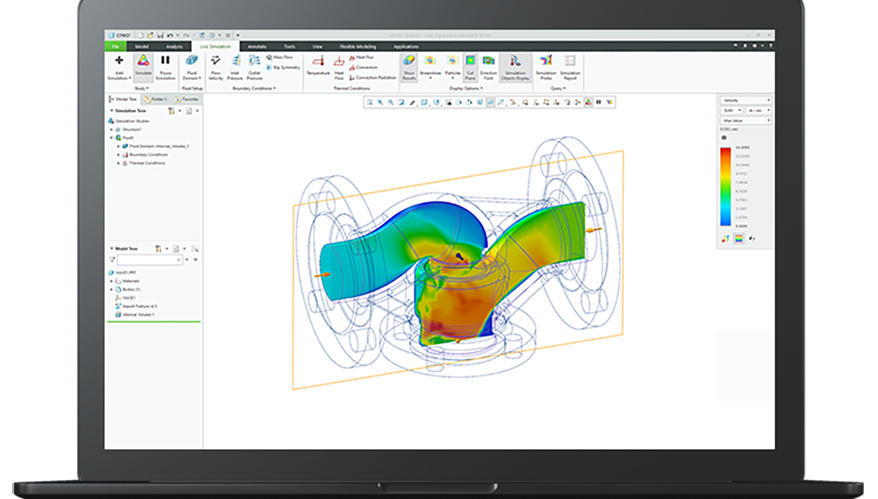

PTC digital design software

PTC digital design software

PTC photo

PARIS — Software companies PTC and Ansys have teamed up to build two products that leverage simulation to speed up the digital design process for engineers.

The first product, Creo Simulation Live, provides engineers with instantaneous static structural, thermal, modal and fluid flow design guidance that gives instant feedback through real-time simulation.

The second, Creo Ansys Simulation, is a high-fidelity tool that leverages Ansys’s advanced simulation capabilities for thermal, structural and modal analysis directly within PTC’s Creo software system.

The idea is to give engineers early insight into product behavior sooner than the traditional process. The technology allows an engineer, “for the very first time, to get insight, directionally and notionally, into whether or not their design is getting better or not with time,” said Jeremy Morse, director of global federal, aerospace and defense computer-aided design sales at PTC.

The two companies forged and “melted in” the “best-in-class [computer-aided design]” with “best-in-class simulation,” Morse said during a panel at the Paris Air Show June 18.

Computer-aided design is a way to digitally create 2D drawings and 3D models of real-world products before they are manufactured.

In many cases, junior engineers, “those that don’t have a lot of time with [computer-aided design], they don’t actually know if they’re improving it or not. This gives all that early insight,” he said.

A video demonstrating the technology showed changes being made to a computer-aided design immediately producing feedback.

Morse said the tools can help alleviate one of the most common problems he hears about: the “valley of death,” which he referred to as “this massive chasm between engineering and simulation.”

Early on, there was promise that computer-aided design could solve this problem alone, but “we all know that didn’t happen, it created its own problem,” Morse said — “its problem of rich digital information, rich digital engineering information, but then still a chasm to simulation.”

“And it’s truly an exciting time to think what happens if you were to bring these two behemoths together to solve some real problems,” he said.

The tools do not replace a simulation expert that “actually has to put the stamp of validation,” but what it does is “closes that valley of death in that chasm. Right now, large, large defense [original equipment manufacturers] would tell you there’s between a 12 and a 16-week backlog between engineering, handing a design off, the simulation, and simulation giving a thumbs up or the thumbs down,” he said.

Many times, there is no information as to why it failed or how to fix it, he said.

“If an engineer could get 80 percent farther … we’re trying to tackle this by any means we can, in eliminating that valley of death or shortening that valley of death,” he said. “If I can get a much, much, much better design that requires one less iteration, that’s 12 weeks. Two less iterations, 24 weeks. That's what we’re talking about.”

In a climate where adversaries are innovating faster than the United States and weapons systems typically take anywhere from five to 15 years to develop, time is of the essence, said Steve Bleymaier, chief technology officer for aerospace and defense at Ansys.

Faster innovation is needed because the threat is innovating faster, he said. The aerospace and defense industries are “still doing it the old way” with physical prototypes and “still taking longer and longer. That’s got to change. It’s got to change because of the threat.”

The tools do not serve as a final validation, “but this certainly puts a tool in the hand of engineers for structural, modal, thermal and fluids, and it puts a tool in the hands of an engineer that they can quickly identify, ‘my design is getting better or it’s getting worse,’” Morse said.

“What if a tool like this combination of these two tools can get you first pass success?” he said. “What if, really, the validation is that good that it can get you almost all the way there? And that’s really what we’ve accomplished here.”